Technology Leading Design Quality at One Excellence

2020 saw the completion of One Excellence and the start of a new standard of design for high-rise buildings in China. Technology is enabling this change and Farrells’s Senior Architectural Designer, Richard Andersen, together with Senior Associate, Matthew Donkersley, discuss the role software enhancements played at One Excellence.

“ At One Excellence we tested the engineering limits – what might appear as a simple curvature in a building, requires real resolve to achieve. Years ago this wouldn’t have been achievable, but with the accessibility to technology that architects have today, we can work more closely with the wider project team and achieve not only our design vision, but most importantly, the client’s. “

– Richard Andersen, Senior Architectural Designer at Farrells

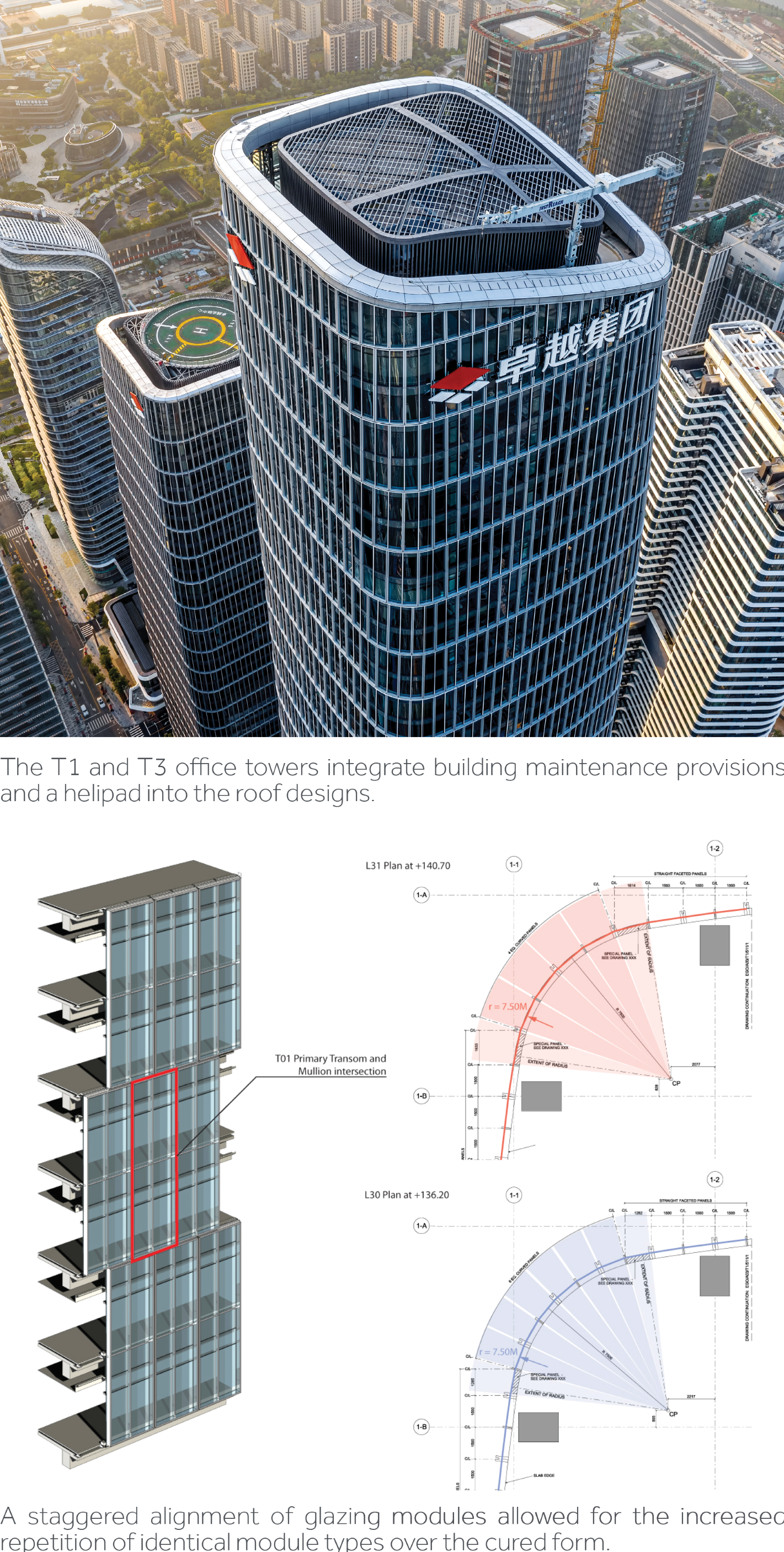

The transformation of China’s cities over the last few decades have led to an increasing number of super-tall towers. Shenzhen is a perfect example of this – over last few decades it has rapidly grown to a metropolis of a staggering 12.7 million people. Located to the west of Shenzhen in the Qianhai district sits our project One Excellence, a vast development of four office high-rises and two residential towers. In creating this new architectural destination, the Farrells team set out to achieve a level of quality often lacking in similar large scale, fast paced projects by using advanced technology to marry both construction processes and aesthetic ambitions.

As design architects, Farrells’ role is not only to push the boundaries in design but respect the challenges that come with designing for the level of density required in today’s urban centres. With over 30 years’ experience in China, the Farrells team understands the complexities that come with construction sites in urban locations. From fabrication constraints, to moving materials around tightly configured locations, logistics are a key consideration for projects teams and require the insight of architects during early design stages.

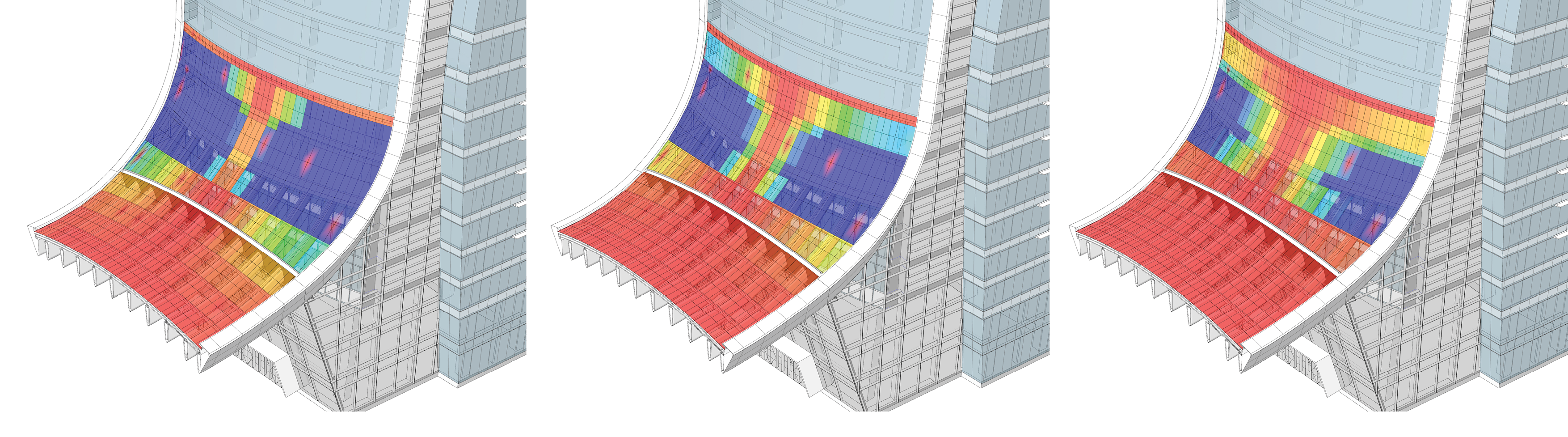

Starting at the distinctive, glimmering 300-metre tower at One Excellence – beneath its striking design lie a series of advances in architectural software. To efficiently resolve the alignment of the glazed panels, over the curved form, in an aesthetically desirable manner is a design feat, only possible through collaboration and deep understanding of the geometry and construction possibilities. Each structure within the site presented Farrells with a unique series of challenges, which were in turn solved with commercially available software such as McNeels Rhinoceros, paired with individually tailored code written by Farrells. This code would be developed to respond in line with the evolving design from the Architect but also accommodate the limitations presented by the regional construction technology available. In the past there was often a disconnect between what software enabled to be created virtually and what could be built physically contributing to poorly constructed buildings and ultimately damaging the reputation of China’s construction industry.

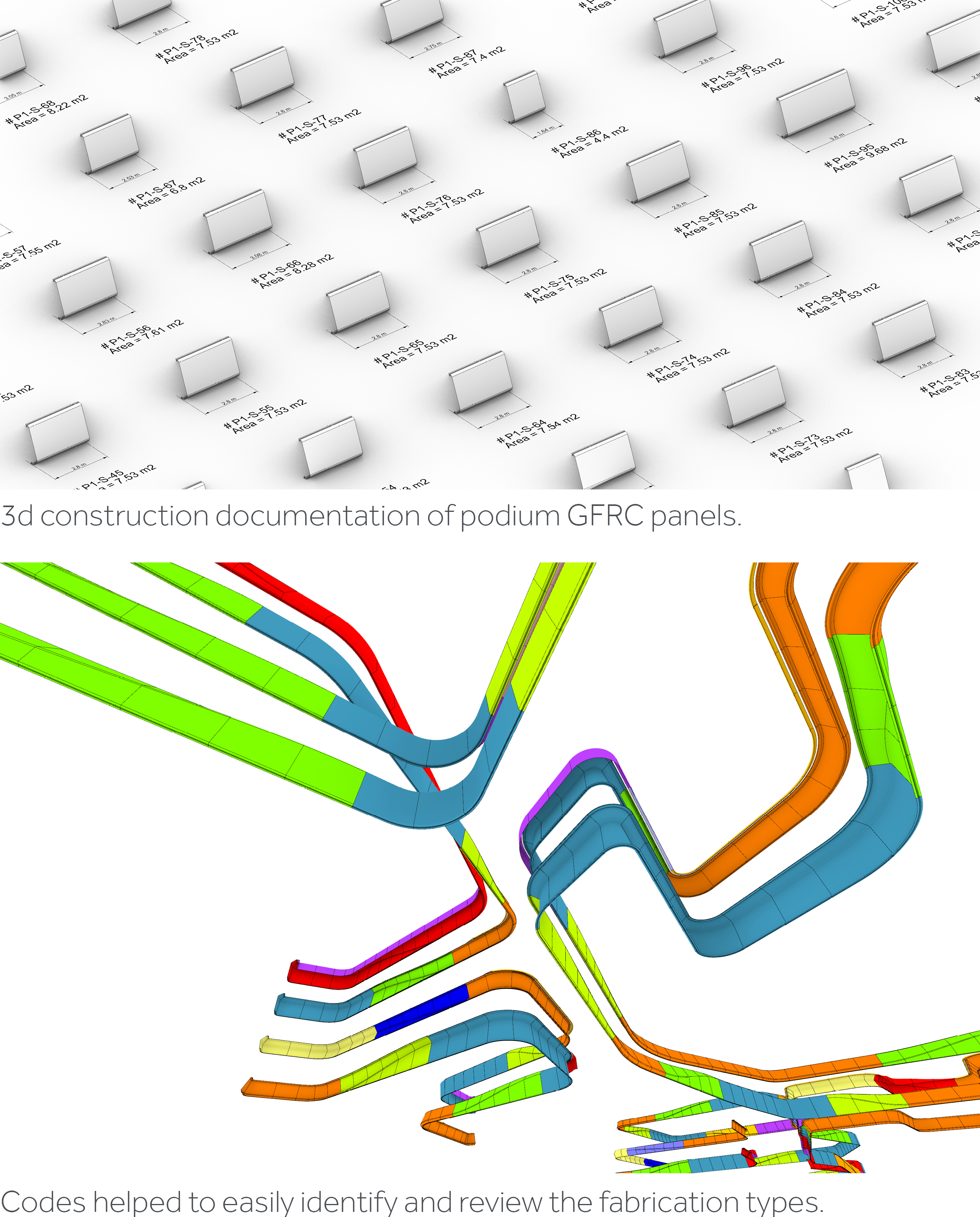

The industry has combatted this with greater teamwork and by embracing workflows that digital tools make available – at One Excellence, Farrells developed the designs of the towers and podia GFRC facades, conscious of the constrains presented by the fabrication, transportation and construction processes, to create ambitious yet buildable designs.

“ Embracing emerging technologies has tangible sustainable benefits – by understanding the precise configuration of panels through software, we can optimize the building forms and panelization strategies to avoid a considerable amount of unnecessary waste. “

– Richard Andersen, Senior Architectural Designer at Farrells

As the first project to be constructed within the Qianhai CBD, it was imperative that One Excellence could be constructed quickly, in line with the wider development plan. Despite this time pressure, Farrells worked tirelessly, ensuring the thousands of panels for the towers and podia were managed through intense data and scripting, resulting in the complex curvature now seen today.

“The codes we used for the podium GFRC panels allowed design studies and changes to be instantly reflected in the construction documentation with feedback on criteria such as material usage and number of unique panel types providing a multi-dimensional understanding of the implications of our design proposals.“

– Matthew Donkersley, Senior Associate at Farrells

The ability for architects to consider construction processes at the early stages of the design process reduces the amount of post-rationalisation that is required later on, sometimes occurring when the architect is no longer involved. Allowing the architect increased control over the ultimate design ensures that the design intent can be better realized, without unexpected or low-quality outcomes.

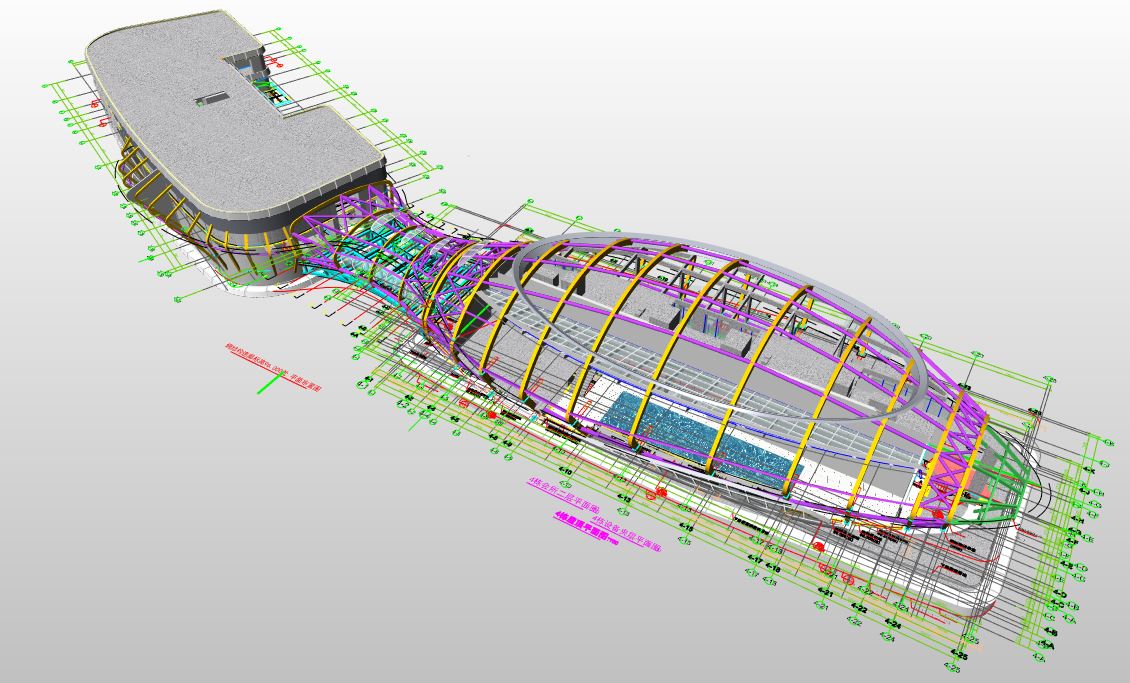

The design and development of the fluid podium Glass Fibre Reinforced Concrete (GFRC) Panels required a dynamic virtual 3D environment. 2D software and drawing process could not effectively communicate the complexity of the proposed geometries, and could not provide an efficient workflow for dealing with the design developments.

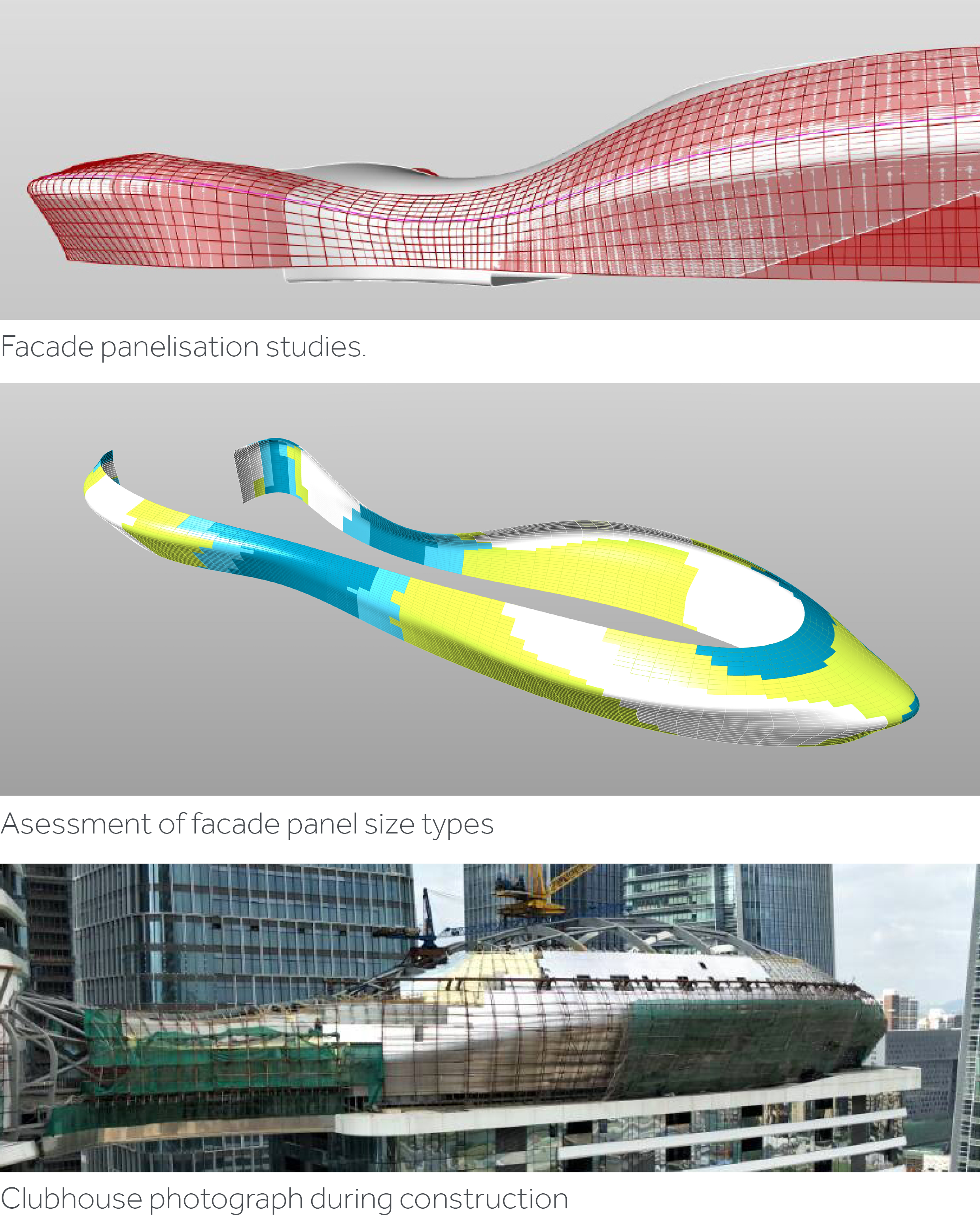

Throughout the design development continuous design modifications were required due to changes to the podium massing and design or due to new information from the contractor such as maximum panels sizes and curvature limitations. The models and codes developed created a virtual environment where developments could be visualised and assessed with projected construction documentation outputs instantly updated.

“Our interest in software is exploring how to use digital tools to create more responsive and efficient design workflows. What we saw with One Excellence is that adopting this approach allows us as architects to have an increased influence on the design outcomes – better pairing design ambition with efficient and sustainable construction processes. “

– Matthew Donkersley, Senior Associate at Farrells

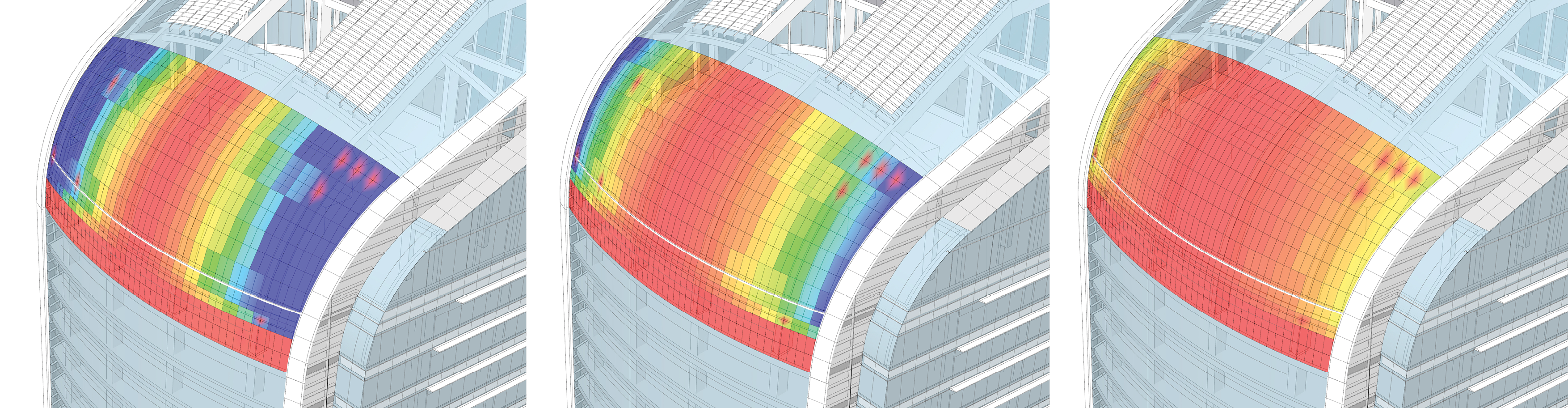

The clubhouse which bridges between the two residential towers was developed with the client to become a feature ‘cloud-like’ element. Similar to the podium GFRC panels the clubhouse geometries could not be efficiently managed and resolved using tradition 2D software and workflows. The 3D model provided an essential virtual environment for continually reviewing the design and coordinating the input from multiple disciplines (namely Structure and MEP). The resolution of the stainless-steel façade presented significant challenges, custom codes were developed to panelise the façade surface and provide colour coded feedback on the suitability of panel types based on known factors such as size and curvature limitations. Additional codes were also used to generate and lay out panel cut patterns for fabrication.

Previously, when designing similar freeform geometries architects may not have the capability or resource to consider the precise resolution of every panel. This process may have been de-linked from the design process and resolved separately by the contractor, with a potentially negative impact on the design outcome. The software used on the design of One Excellence facilitated instant feedback between concept design and construction possibilities enabling Farrells to have an informed design approach with control over each panel and joint line.

“The willingness to embrace technology transcends the One Excellence Project and is ingrained within China’s approach to the future development of its cities. This is facilitating significant leaps forward with respect to reduced energy usage and sustainable design solutions. “

– Matthew Donkersley, Senior Associate at Farrells

The rapid adoption of new technologies is evident throughout China’s emerging mega cities. For instance, Shenzhen is the first city in the world to have an entirely electric bus fleet, cutting bus related Co2 emissions by 48%. Transit-oriented developments such as One Excellence provide positive connections to Shenzhen’s energy efficient mass transit systems. Reducing a reliance on cars dramatically reduces a cities transport energy usage – an important consideration given that transport accounts for between 25-30% of global energy consumption. The integration of the district cooling centre on the One Excellence site also offers significant energy saving benefits to both the One Excellence development and also the wider Qianhai CBD area.

One Excellence is created with a sustainable future in mind, setting new efficiency standards in high-density architectural design and sustainable construction. Farrells approach to the project demonstrates that digital tools can offer pathways for complex forms to be efficient, rational and sustainable. This approach combined with design strategies that help to cultivate resilient communities and support occupant wellbeing, offers a prototype for the future of sustainable high-density city making.

Photo credit: Rex Zou & Eric Cheung